OEM Customized Cable - Concrete Mixer Drum Roller Bare Roller – ANCHOR

OEM Customized Cable - Concrete Mixer Drum Roller Bare Roller – ANCHOR Detail:

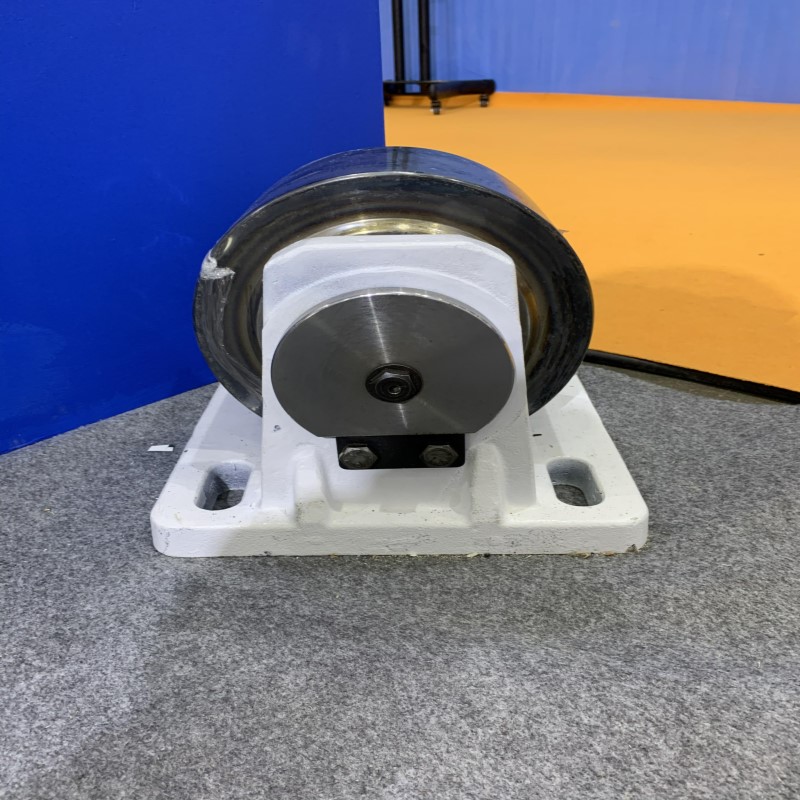

Concrete mixer drum rollers are units of the rotary motion mechanism of the concrete mixer drum. The purpose of drum rollers is to support and ensure the drum stability on the rear console structure. The drum rollers are mounted on the rear console of concrete mixer in the amount of 2 pieces – on the left and on the right. The rolling ring, which is the structural element of the drum, is the main support of the mixer on the rollers. For double large capacity mixers, double drum rollers are used. The wide distance between rdrum rollers ensures stable drum positioning.

The components of the rollers for concrete mixers except the roller body itself are: bearing housings, roller bearings, covers, bolt sleeves, pins, bolt washers and nuts. The design and geometry of concrete mixer rollers features this assembly with high resistance to load transfer even in case of an overloading the mixer. The application and regular check-up of lubrication of concrete mixers with greasy lubricants for high loads prevents premature wear of rolling bearings in the assemblies. The rollers for concrete mixers themselves are usually protected with additional covers

OEM Part Number:

Schwing 30386702

Beck 40550

Continental 80357100

Terex 40830

Mcneilus 150440

- Bare roller forging

- Roller material 40Cr

- Roller surface heat treated: Hardness 50-55HRC

- Durable bearings inside

- High quality oil seal

| NO. | EXTERNAL DIAMETER(MM) | WIDTH(MM) | INNER DIAMETER (MM) | WITH SHAFT OR WITHOUT SHAFT |

| 1 | 200 | 90 | 50 | WITHOUT |

| 2 | 200 | 102 | 25 | WITH |

| 3 | 200 | 100 | 25 | WITH |

| 4 | 248 | 120 | 38 | WITH |

| 5 | 250 | 90 | 40 | WITH |

| 6 | 250 | 90 | 35 | WITHOUT |

| 7 | 250 | 90 | 50 | WITHOUT |

| 8 | 250 | 100 | 50 | WITHOUT |

| 9 | 250 | 110 | 38 | WITHOUT |

| 10 | 250 | 110 | 50 | WITH |

| 11 | 250 | 110 | 60 | WITHOUT |

| 12 | 250 | 120 | 38 | WITH |

| 13 | 250 | 120 | 50 | WITHOUT |

| 14 | 250 | 120 | 60 | WITHOUT |

| 15 | 280 | 90 | 50 | WITHOUT |

| 16 | 280 | 90 | 35 | WITHOUT |

| 17 | 280 | 92.5 | 50 | WITHOUT |

| 18 | 280 | 95 | 50 | WITHOUT |

| 19 | 280 | 100 | 50 | WITHOUT |

| 20 | 280 | 110 | 50 | WITH |

| 21 | 280 | 120 | 50 | WITHOUT |

The drum is turned at high speed (12 – 15 rpm) for about 50 revolutions while at the production facility, which allows for a quick check of batch characteristics. Their main purpose is to lift the materials as the drum rotates. In each rotation, the lifted material drops back into the mixer at the bottom of the drum and the cycle starts again.

Different sizes and types of rollers should be distinguished – from rollers with a diameter of DN200, through DN220, DN250, ending with rollers DN280. Depending on the size, they are designed for the proper size of mixer drums (for example 7m3, 9m3 and larger) and a given roller model is dedicated to each manufacturer of concrete mixers. Most often: IMER, LIEBHERR, STETTER, Intermix, LEŻAJSK, CIFA and others.

Complete rollers for concrete mixers as well as individual components and parts are produced from high-quality materials. High-quality bearings used in complete rolls guarantee the bearing’s life.

In order to receive more information, please contact us.

Product detail pictures:

Related Product Guide:

The very rich projects management experiences and one to one service model make the high importance of business communication and our easy understanding of your expectations for OEM Customized Cable - Concrete Mixer Drum Roller Bare Roller – ANCHOR , The product will supply to all over the world, such as: Hanover, Swaziland, Kuwait, Our factory is equipped with complete facility in 10000 square meters, which makes us be able to satisfy the producing and sales for most auto part solutions. Our advantage is full category, high quality and competitive price! Based on that, our products win a high admiration both at home and abroad.

Adhering to the business principle of mutual benefits, we have a happy and successful transaction, we think we will be the best business partner.