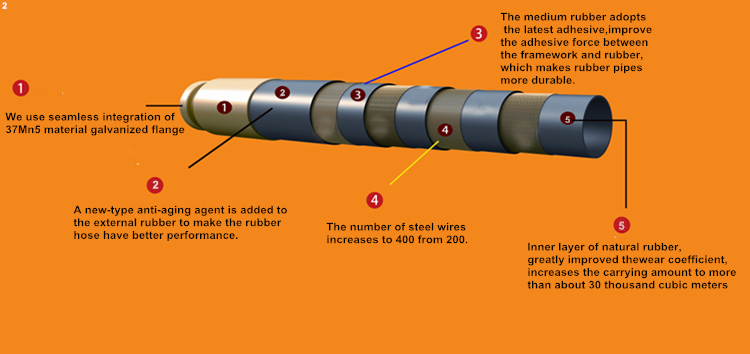

1. High-pressure Pipe heads are upgraded into seamlessly integrated 37Mn5 manganese alloy pipes, and conducted quenching treatment make them much more wear-resisting.

2. The internal rubber is made of quality natural rubber, new-type accelerants and green anti-aging agents by consulting the technical parameters of the rubber of airplane tires. The abrasion of the internal glue enhanced from 0.111 cubic centimeters to 0.069 cubic centimeters, which increases the carrying amount of rubber hose to more than about 30 thousand cubic meters.

3. The medium rubber adopts the latest environmental-friendly adhesive in the world to reduce pollution and improve the adhesive force between the framework and rubber, which makes rubber pipes more durable.

4. Conduct a tensile test on steel wire for each batch of rubber hose and conduct professional adjustments. The number of steel wires increases to 400 from 200. Their diameter reduces from 1.8 mm to 1.2mm. Therefore, the pliability of rubber hose is improved greatly. Experiments show that the pressure-resistant and explosion-proof performance of the rubber hose has been improved greatly.

5. A new-type anti-aging agent is added to the external rubber to make the rubber hose have better performance in resisting blows, stretching, aging and ultraviolet rays.

Post time: Apr-22-2021