Manufactur standard Fan - Fan – ANCHOR

Manufactur standard Fan - Fan – ANCHOR Detail:

Description

Fan also known as “turbofan engine”. It refers to a gas turbine engine in which the gas injected by the nozzle and the air discharged by the fan produce a reaction thrust. It consists of a compressor, a combustion chamber, a high-pressure turbine (to drive the compressor), a low-pressure turbine (to drive a fan) and an exhaust system. The first three parts are called the “core engine”. The available energy in the gas flowing out of the core engine is used to drive the low-pressure turbine to drive the fan, and the other part is used in the nozzle to accelerate the ejected gas. The bypass ratio is closely related to fuel consumption. The first generation of turbofan engines that appeared in the late 1950s had relatively low bypass ratio, compressor boost ratio and gas temperature before the turbine.

The structure of the FAN is actually that there are 1-2 low-pressure (low-speed) turbines added to the rear of the turbojet engine. These turbines drive a certain number of fans and consume a part of the gas exhaust kinetic energy of the turbojet engine (core engine). , Thereby further reducing the gas discharge speed. Part of the air flow sucked in by the fan is sent to the compressor (termed “internal duct” in terminology), just like an ordinary jet engine, and the other part is directly discharged from the periphery of the turbojet engine casing (“outer duct”). Therefore, the gas energy of the turbofan engine is distributed to the two exhaust air flows generated by the fan and the combustion chamber respectively. At this time, in order to improve thermal efficiency and increase the temperature in front of the turbine, more fuel gas energy can be transferred to the outer duct airflow through the low-pressure turbine-driven fan through proper turbine structure and increased fan diameter, thereby avoiding a significant increase in exhaust velocity. In this way, thermal efficiency and propulsion efficiency have been balanced, and the efficiency of the engine has been greatly improved. Higher efficiency means lower fuel consumption and longer range of the aircraft. However, the large fan diameter increases the windward area of the engine, so turbofan engines with a bypass ratio greater than 0.3 are not suitable for supersonic cruise flight. Although the turbofan engine reduces the exhaust speed, it does not reduce the thrust, because reducing the exhaust speed increases the (external) exhaust flow. From the perspective of bypass ratio, turbofan engine is a compromise between turbojet engine and turboprop engine.

Packing

Carton Boxes, or according to clients’ request.

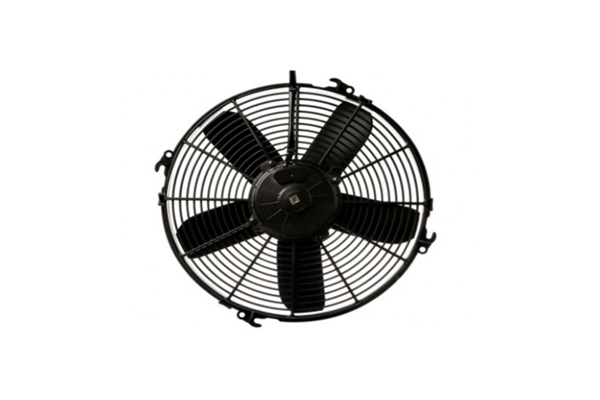

Product detail pictures:

Related Product Guide:

We aim to find out quality disfigurement from the production and supply the best service to domestic and overseas customers wholeheartedly for Manufactur standard Fan - Fan – ANCHOR , The product will supply to all over the world, such as: Danish, Uruguay, Chile, As a way to use the resource on the expanding info in international trade, we welcome prospects from everywhere on the web and offline. In spite on the high quality items we offer, effective and satisfying consultation service is supplied by our qualified after-sale service group. Item lists and detailed parameters and any other info weil be sent to you timely for the inquiries. So please make contact with us by sending us emails or call us when you've got any questions about our organization. ou could also get our address information from our site and come to our enterprise. We get a field survey of our merchandise. We are confident that we'll share mutual accomplishment and create solid co-operation relations with our companions within this market place. We're seeking forward for your inquiries.

The accounts manager made a detailed introduction about the product, so that we have a comprehensive understanding of the product, and ultimately we decided to cooperate.