Factory Cheap Hot Pressure Spring - Cutting Ring Schwing – ANCHOR

Factory Cheap Hot Pressure Spring - Cutting Ring Schwing – ANCHOR Detail:

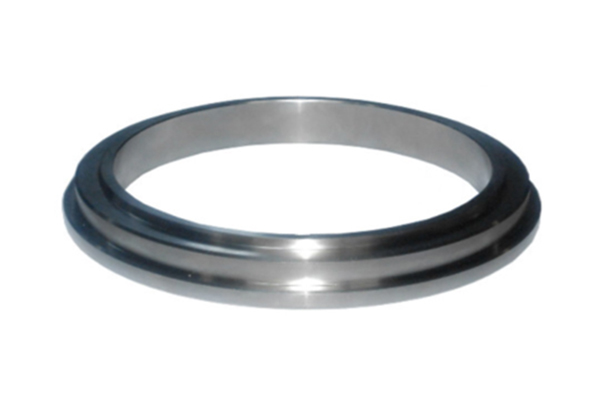

The cutting ring is also called the wear ring, which is an important part of the concrete pump truck. Shaped like a torus. The working state is doing shearing movement, so it is called cutting ring.

At present, the commonly used production materials are: (1) High chromium alloy cast iron. (2) Tungsten carbide. (3) Cemented carbide. (4) Alloy ceramics.

Spectacle plate, cutting ring, rubber spring, special-shaped nut, transition sleeve, seal, big and small bearing and S-tube welded body constitute the S-tube valve.

The spectacle plate and cutting ring mainly play the following roles:

Sealing function: They mainly work with rubber springs, and the gap is automatically compensated by pressure self-balancing and rubber springs, so that the floating cutting ring has a self-sealing effect, thereby increasing the delivery pressure of the S tube valve.

Cost reduction effect: Due to the effect of the spectacle plate and the cutting ring, they replace the wear between the feed port and the material cylinder, and protect the service life of both.

Their working principle is: under the action of the pre-tightening force of the unfolding nut, the rubber spring is compressed, and the cutting ring closely fits the spectacle plate. The cutting ring and the spectacle plate belong to the relative motion coupling. After the wear occurs, the rubber spring can rely on its own elasticity to compensate the wear of the spectacle plate and the cutting ring and eliminate the wear gap. When the wear of the cutting ring reaches a certain level, the compression of the rubber spring is zero, and there is no pressing force on the cutting ring. The unfolding nut can be tightened, and the S tube welded body can be tightened back to restore the compression of the rubber spring. The rubber spring is compressed and the gap is compensated. In this way, the sealing performance of the spectacle plate and the cutting ring is well ensured.

Part number: S020318003

Usage/Application: concrete pump

Size: DN230

1.30,000-60,000 m³ service life, original produced wear plate

2.Double-ring segemental alloy structure can effectively solve the problem of alloy collapse.

3.Over sized alloy width, better sealing performance, more wear-resisting.

Product detail pictures:

Related Product Guide:

To fulfill the customers' over-expected satisfaction , we have now our strong crew to provide our greatest general assistance which incorporates promoting, gross sales, planning, creation, top quality controlling, packing, warehousing and logistics for Factory Cheap Hot Pressure Spring - Cutting Ring Schwing – ANCHOR , The product will supply to all over the world, such as: Angola, Manila, Comoros, We have been fully aware of our customer's needs. We deliver high quality products, competitive prices and the first class service. We would like to establish good business relationships as well as friendship with you in the near future.

It's really lucky to find such a professional and responsible manufacturer, the product quality is good and delivery is timely, very nice.